Home › About Packserv › Global Partnerships › Pillar Technologies Technical Services › Pillar Technologies Preventative Maintenance

Pillar Technologies Preventative Maintenance

At the change of each season, it’s always good practice to take care of your preventative maintenance issues, i.e. change the batteries in your smoke detectors, change the air purifier filter on the home furnace, clean out the dryer vent, etc. With this in mind, Pillar Technologies likes to remind you to take a few moments to do the requested maintenance necessary on your induction cap sealer.

These few minutes of upkeep are factory recommended every few months. Simply run through the check-list for your type of sealer(s).

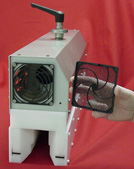

UNIFOILER™ Waterless Induction Sealers:

Maintenance is limited to keeping the front panel and fan filters clean.

Use a soft cloth and window cleaner or mild detergent to clean the front panel. Do not use solvent; solvent will damage the plastic panel overlay.

Clean the fan filter located on the back of the power supply and the filter on the end of the sealing coil. Filters should be cleaned with plant air or vacuumed occasionally. Check the fans behind the filters for accumulation of dust. Remove any dust carefully with dry compressed air. (Disconnect incoming power before cleaning.)

Lubricate the jack screw that carries the power supply and sealing coil up and down during height adjustments. Lubricate the wheels on your portable cart (if applicable).

FOILER™ Water-Cooled Induction Sealers:

Power Supply

- Check the fan and heatsink for accumulation of dust

- Remove any dust carefully with dry compressed air.

Coil Support

- Clean the lead screw if it accumulates dirt.

- A little silicone spray on the screw thread will keep the crank turning smoothly.

- Do not use cleaners or lubricants that are not compatible with the Delrin slide blocks.

Remote Panel

- When cleaning, do not use solvents.

Coil

- If the coil is routinely mounted and dismounted, see that the water connection fittings are in good order.

Water Cooler

- Periodically remove dust from the radiator with compressed air.

- Check the water filter for sediment, clean or replace as necessary.

- Periodically empty and flush the water reservoir.

- Check the flow switch for proper functionality.

Induction cap sealing has a wide variety of applications in many different industries. At Pillar Technologies Australia we continuously work with our clients to develop new markets and test our cap sealing process in new applications.

If you have a unique application, contact Pillar Technologies Australia today to schedule an evaluation.

Packaging Machinery Made Easy

Take your business to the next level with Australia’s leader in packaging equipment and services.

Short & Long term Hire, Buy, Rent-To-Buy and Leasing options.