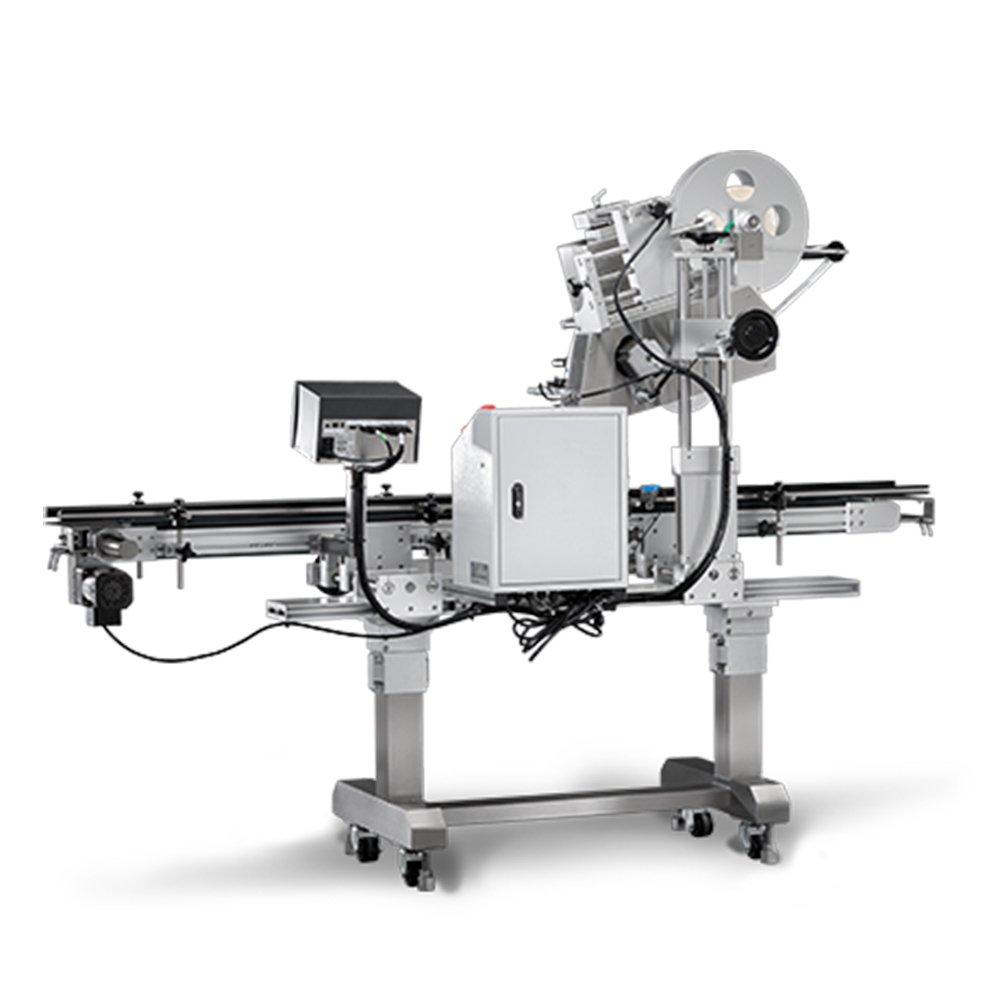

Pack Leader’s PL-211D Automatic Top, Bottom and Clamshell Labeller is suitable for a wide range of top labelling needs including trays, boxes, chipboard containers, bags and even caps on bottles. This machine features a belt conveyor to offer greater width and traction versus slat conveyors to cater to all product types.

This variant of the PL-211 is specifically designed with clamshell style containers in mind.

It utilizes a PLC system combined with a touch screen, an in-built digital counter and a self-diagnostic LED on the panel. This synchronizes control on the entire machine structure, which allows stable operation regardless of production speed.

The PL-211D Automatic Top, Bottom and Clamshell Labeller is suitable for a wide range of top labelling on flat package products. A simple, tool-free change is all that is required for changeovers, allowing maximum production efficiency.

All in all, these features add up to a machine that is mobile, stable, flexible, and efficient.