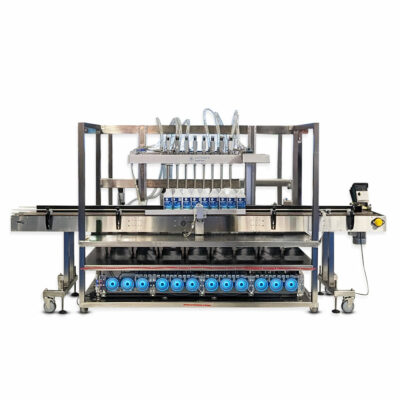

Pack Leader’s PRO-625 Pro Front & Back Wipe-on Labeller is a part of the extraordinary fleet of high-quality, versatile labelling machines on offer by Packserv. This machine offers fully automated dual labelling heads for wipe-on application of double-sided containers and can also be easily configured for single-sided wipe-on application. An additional extra can be purchased to allow this machine to complete wrap-around applications of cylindrical containers.

Designed as a continuous, reliable high-speed labelling machine, it’s manoeuvrable and simple to change between production lines or to remove it for cleaning. Manufactured in strict compliance with GMP standards the PRO-625 Pro is made from 304 grade stainless steel and high quality aluminium which ensures longevity even in the harshest of environments.

The PRO-625 Pro incorporates a high-quality LCD control panel featuring inbuilt trouble-shooting and training for operators to ensure minimal downtime on your production schedule. Additionally, the conveyor and labelling heads are all automatically synchronised via the control panel to ensure perfect labelling time and time again, with minimal setup when changing between products.