In 2007, Nathan Wardell launched the packaging machinery company, packserv, not knowing the stormy economic seas that lay ahead. But in reflecting on the company’s history, Wardell shares what he has learnt and implemented to make packserv one of the country’s leading packaging machinery specialists.

Looking back 10-20 years ago, if someone had asked me what I would be doing and what Packserv would look like, I never would have imagined the journey that unfolded. It certainly hasn’t been without its challenges, but I’ve been striving to adapt as quickly as possible to the ever-changing landscape of business.

In the early days, I built my first business, Rentafill, by putting in long hours and continuously improving my skills. The growth of Rentafill was directly proportional to my hard work and the rate at which I learned to do things better. However, Packserv’s story took a different path.

When I decided to start Packserv, my life was about to undergo a significant change. My partner and I had just welcomed our first child into the world, and surviving on a single income was a challenge in itself. But the real shock came when my father informed me that he was retiring and selling the business – not to me, but to someone else. While initially upset, I saw the opportunity and decided to start Packserv from scratch. I believed that hard work and continuous improvement would lead to success once again. However, I soon discovered that the second time around, things wouldn’t be as straightforward.

WEATHERING THE STORM FRONT

Within a year of starting Packserv, the first wave of the Global Financial Crisis (GFC) hit in 2008, wiping out many established businesses in the lower end of the market. The second wave struck in 2009, causing the finance market to dry up. This was followed by a recession, a manufacturing sector slump, a property crash, and the ultimate challenge – the global pandemic. And now, we face interest rates and inflation. Despite the relentless series of challenges, I held on, believing the saying that whatever doesn’t kill you only makes you stronger.

Amidst the hardships, one positive outcome of the Covid-19 pandemic was a renewed sense of awareness regarding Australia’s overreliance on international supply chains and imports for basic products. We import approximately $250 million worth of packaging and small machinery while only exporting around $5 million. Similarly, we import nearly $15 billion worth of food annually, despite having ample land for food production and farming. This realization has fuelled my passion for domestic manufacturing and reducing our dependence on imports.

After nearly three decades of running a business in Australia, especially in the industrial and manufacturing sector, I’ve come to believe that “resilience” is the key to success. As Mark Bouris coined in his book, resilience is what it takes to weather the storms and emerge stronger.

GROWTH AND SUCCESS FROM DIVERSIFICATION

Curious about our competitors in the market, I recently researched major players in our space. To my surprise, many of them were started between 1940 and 1980, making Packserv, with its 17 years in business, still a relatively young player. Nevertheless, we’ve managed steady growth, and last year we grew at a rate of 60%.

Our focus on diversification has been pivotal in our success. At Packserv, we offer a rental solution, backed by technical support and onsite services, along with our own range of machinery, parts, and accessories. Understanding that different clients have unique needs, we provide various delivery models and support options, including training, maintenance, and installation assistance.

HOME GROWN RELIABILITY

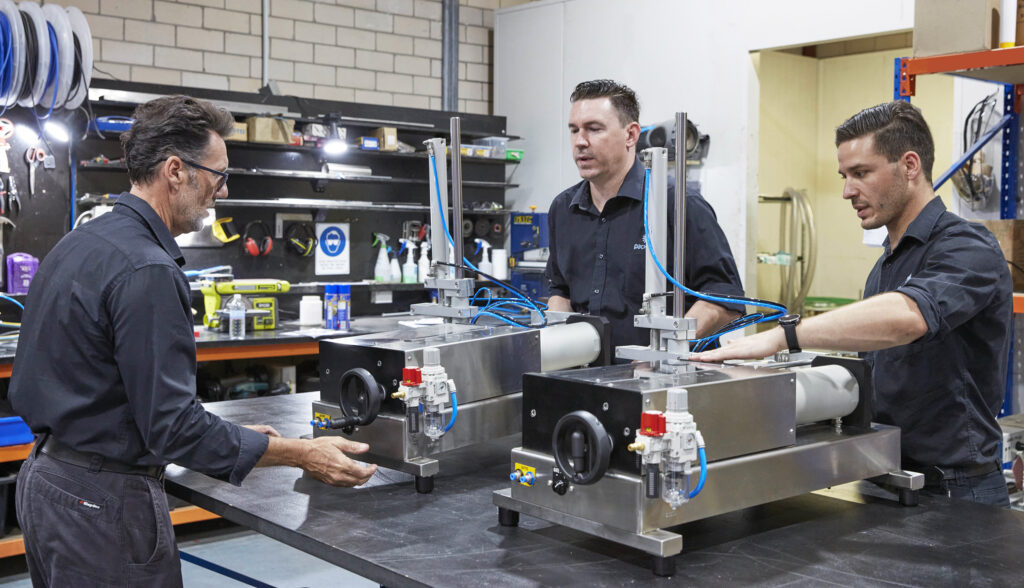

The strength of our domestic manufacturing became evident during the Covid-19 pandemic when many international supply chains faltered. While other businesses faced disruptions due to imported components, we remained almost fully self-sufficient, thanks to our in-house engineering capabilities, machining equipment, and CAD/CAM capabilities. We were able to manufacture our components and build fully automatic lines in our warehouse in Marrickville, showcasing the benefits of being a true Aussie manufacturer.

Packserv primarily focuses on designing and building packaging machinery for the Fast Moving Consumer Goods (FMCG) market. With offices and support services in Sydney, Melbourne, Brisbane, Adelaide, and Perth, we provide technical support and onsite services to manufacturers and contract packers across the country. Our growth over the last financial year reflects the resilience of our local market and the strong efforts of onshore manufacturers to ramp up their production.

CONTINUAL REVIEW AND COLLABORATION

In my quest to continually improve our offerings, I’ve spent a significant amount of time analysing and refining different aspects of the business. By breaking down processes and isolating their functions, we constantly ask ourselves how we can do things better. This approach reflects in the quality, dependability, durability, and performance of the machinery we produce.

Amidst the challenges and adversities, one of the most exciting endeavours at Packserv is the development of our cutting-edge automatic liquid filling machine. This project has become a symbol of innovation, collaboration, and the future of Australian manufacturing.

When it comes to this new machinery, we are leaving no stone unturned. Multiple teams, including esteemed academic institutions such as UTS and the USYD additive manufacturing hub, are actively involved in its creation. The goal is not only to improve upon existing technologies but also to pioneer and design elements for unrivalled reliability, accuracy, adjustment, and lifespan.

The excitement doesn’t just lie in the improvements we are making to the existing machine. Rather, the real thrill is in our vision for the new line of machinery that will accompany it. Incorporating state-of-the-art technology, world-class standards, and unparalleled performance, this new range will represent the pinnacle of Australian manufacturing prowess.

As we approach the highly anticipated APPEX 2024, our teams are working tirelessly to bring these innovative machines to fruition. The passion and dedication invested in this project have been nothing short of remarkable, and I couldn’t be prouder of the talents that make up the Packserv family.

Collaboration has been the cornerstone of our approach to this cutting-edge machinery project. Teaming up with UTS has been a game-changer, enabling us to develop a digital platform that will drive the high-speed production and automation of FMCG production lines. It’s an ambitious endeavour, but the potential impact on the industry is immeasurable.

The journey ahead is filled with excitement and promise. The new range of machinery we are developing will not only meet but surpass international standards. The possibilities are endless, and we are eager to see these innovations contribute to the growth and success of our customers and the Australian manufacturing sector as a whole.

“By breaking down processes and isolating their functions, we constantly ask ourselves how we can do things better. This approach reflects in the quality, dependability, durability, and performance of the machinery we produce.”

See the article in Food & Drink Business Magazine here