Container filling is an important control point within production lines, where inaccuracies can lead to product loss, contamination and costly downtime. Additionally, workforce shortages and high operator turnover require frequent operator training which can be time-consuming and expensive. Machines need to be intuitive, reducing the learning curve and minimising manual adjustments to reduce downtime and ensure consistent throughput and optimal line efficiency.

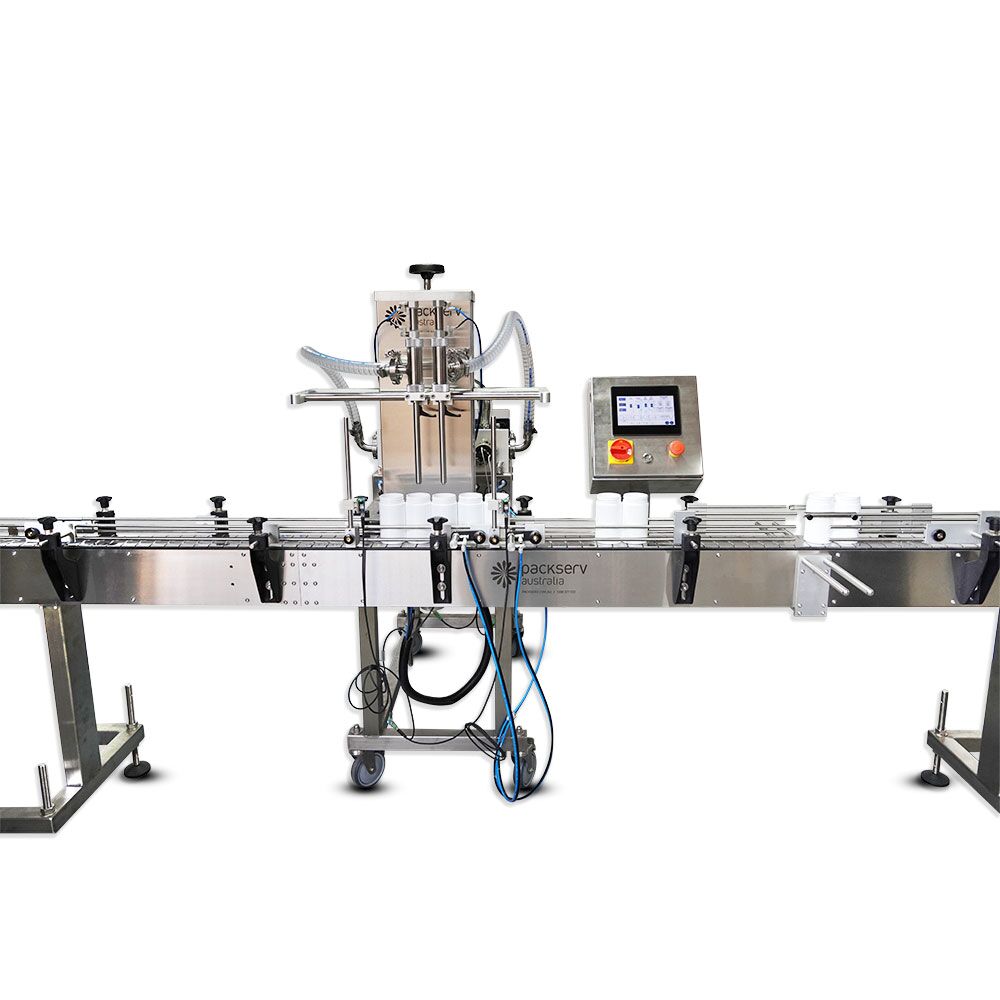

Why Choose Packserv’s PLC Twin Head Filler?

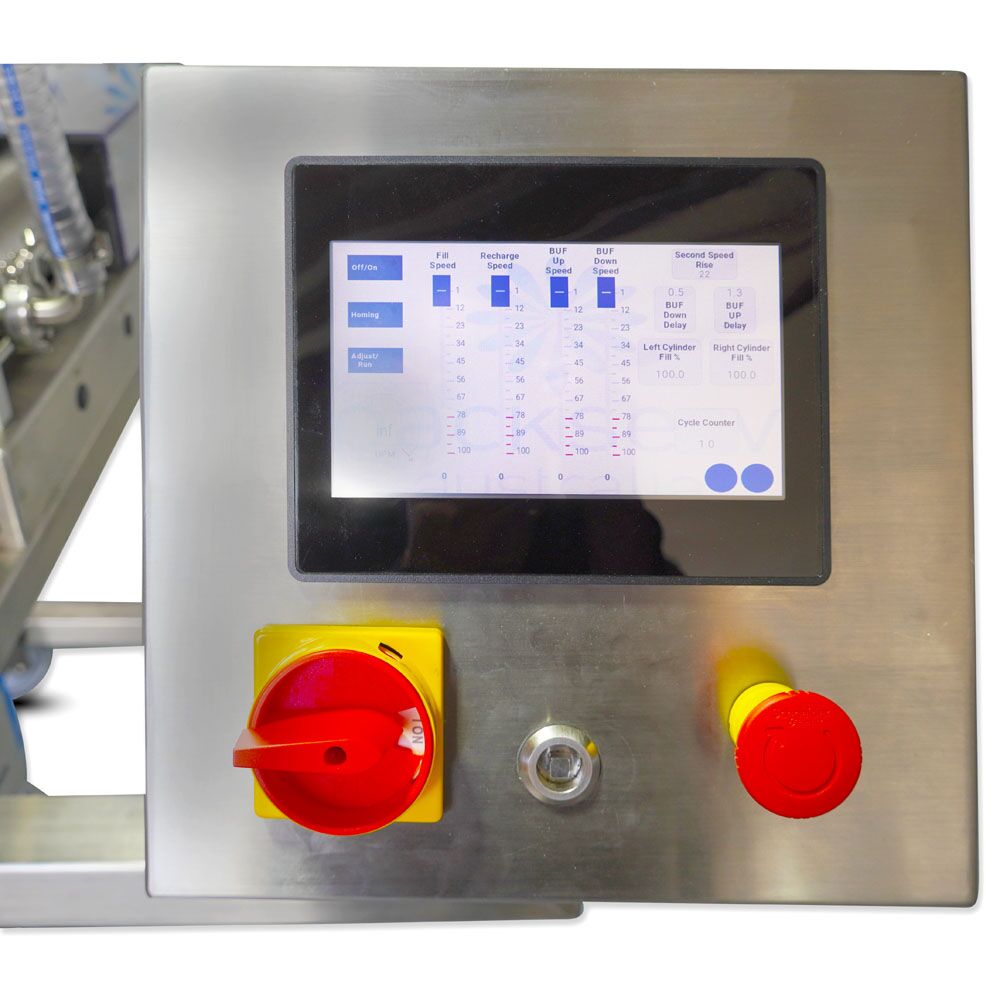

Easy Touchscreen Control with Ultimate Configurability

- Preloaded adjustable settings make product changeovers fast, eliminating manual adjustments and minimising downtime. Machine operators can set individual cylinder and nozzle fill volumes, BUF and cylinder speeds with ease using an intuitive HMI touchscreen. Cover your entire range of products with the use of a multi-shot function.

Smart Automation

- Real-time data monitoring tracks cycle times, resource usage and energy consumption to optimise efficiency.

Locally Designed, Manufactured and Supported

- Manufactured in Australia with local parts and technical support, you’ll experience faster service and minimal downtime.

Built for Today’s Workforce

- This machine is designed to be user-friendly for machine operators, ensuring that performance and efficiency are optimised. Inbuilt with helpful manuals and guides to ensure set up and troubleshooting can be completed by your whole workforce to eliminate downtime.

Modular and Scalable

- Easily integrates with Packserv’s cappers, labellers, printers, tables and conveyors, allowing you to grow your production easily and cost-effectively.

Centralised Control System

- Have one central HMI and PLC able to control and coordinate the functions of all your ancillary equipment such as conveyor and turntable speeds.

Whether you’re upgrading from manual processes or scaling up your automation, the PLC Twin-Head Filler delivers a practical, affordable entry into Industry 4.0 manufacturing without the heavy price tag or complexity.

Reviews

There are no reviews yet.