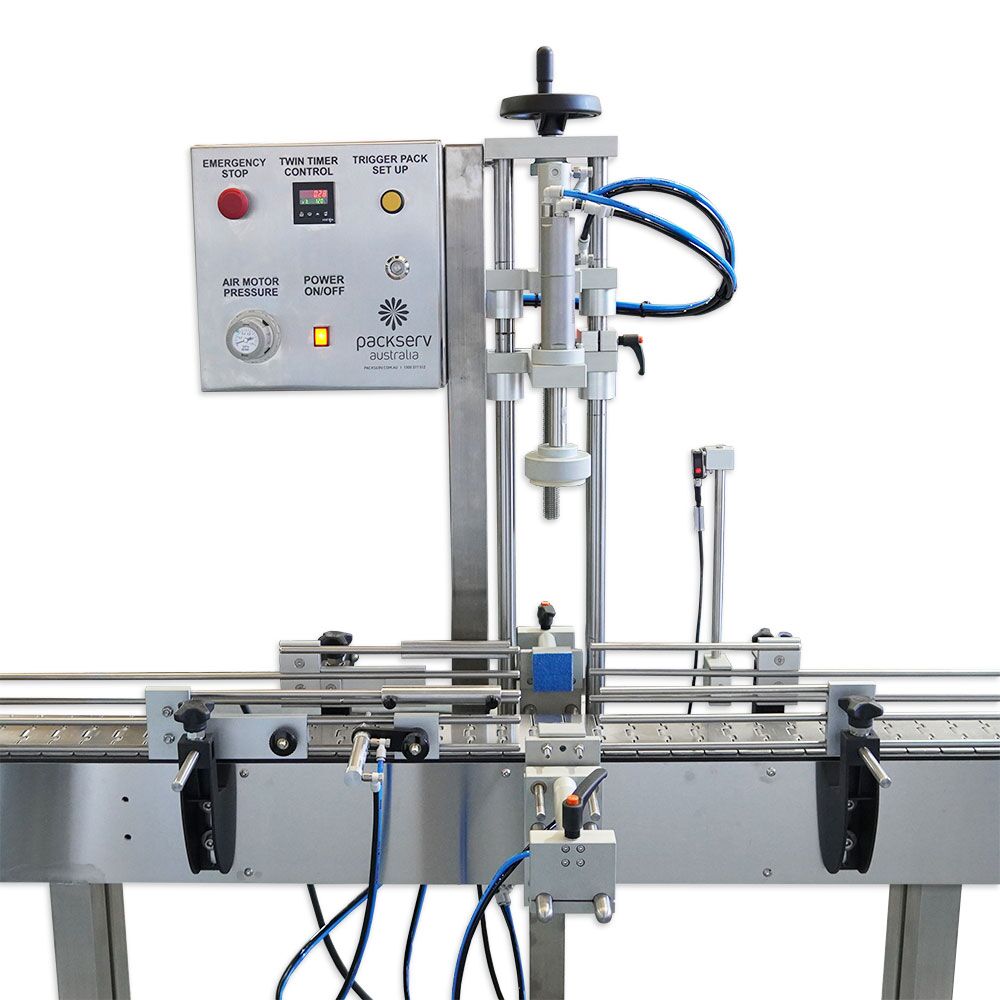

Our PCM-1A-E Auto Capper Electronic Timer is an automatic cap tightener designed to mount onto a continuously running slat-type conveyor. The PCM-1A-E is capable of tightening a range of closures at rates of up to 60UPM (units per minute). It is capable of tightening any kind of screw-on or push-on closure. When utilised with our PT-7 trigger-pack unit the equipment can additionally tighten trigger-packs, pump and mist-spray closures.

During operation, containers will arrive at the Auto Capper by an inline conveyor, with caps pre-positioned upstream either manually or by automatic cap placement equipment. A photo- electric sensor or whisker switch detects the presence of a container and initiates the machine operation through an electronic timer control unit which in turn activates the tightening head, jaws and gates system.

The control unit provides a comprehensive yet simple control of all the different elements. This ensures any container and closure type can be adequately and efficiently tightened while still offering fast set-ups and container changeovers. The pneumatic controls ensure optimal ease of use for the operator.

The PCM-1A-E Auto Capper is supplied with a conveyor or conveyor mounting frame, container gating and clamping, and jaws (non-marking). This can be contoured to the individual container profile or one of our existing templates can be used to ensure universal container application. Jaws for glass containers come with plastic slippers to prevent the container from scoring the conveyor during the bottling process.

*Rent: Brand and model may vary. The machine will be identical in function.

See Also: Packserv Capping Machines | Packserv Australia

Reviews

There are no reviews yet.