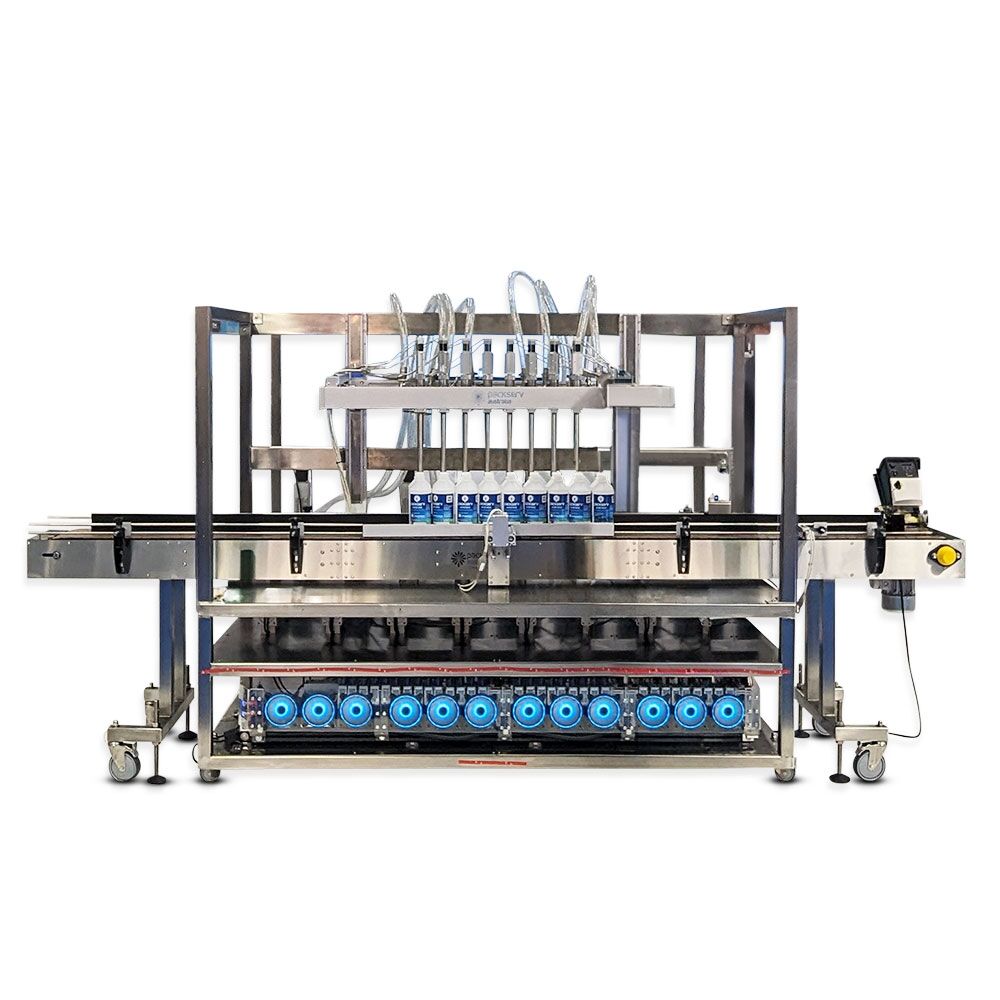

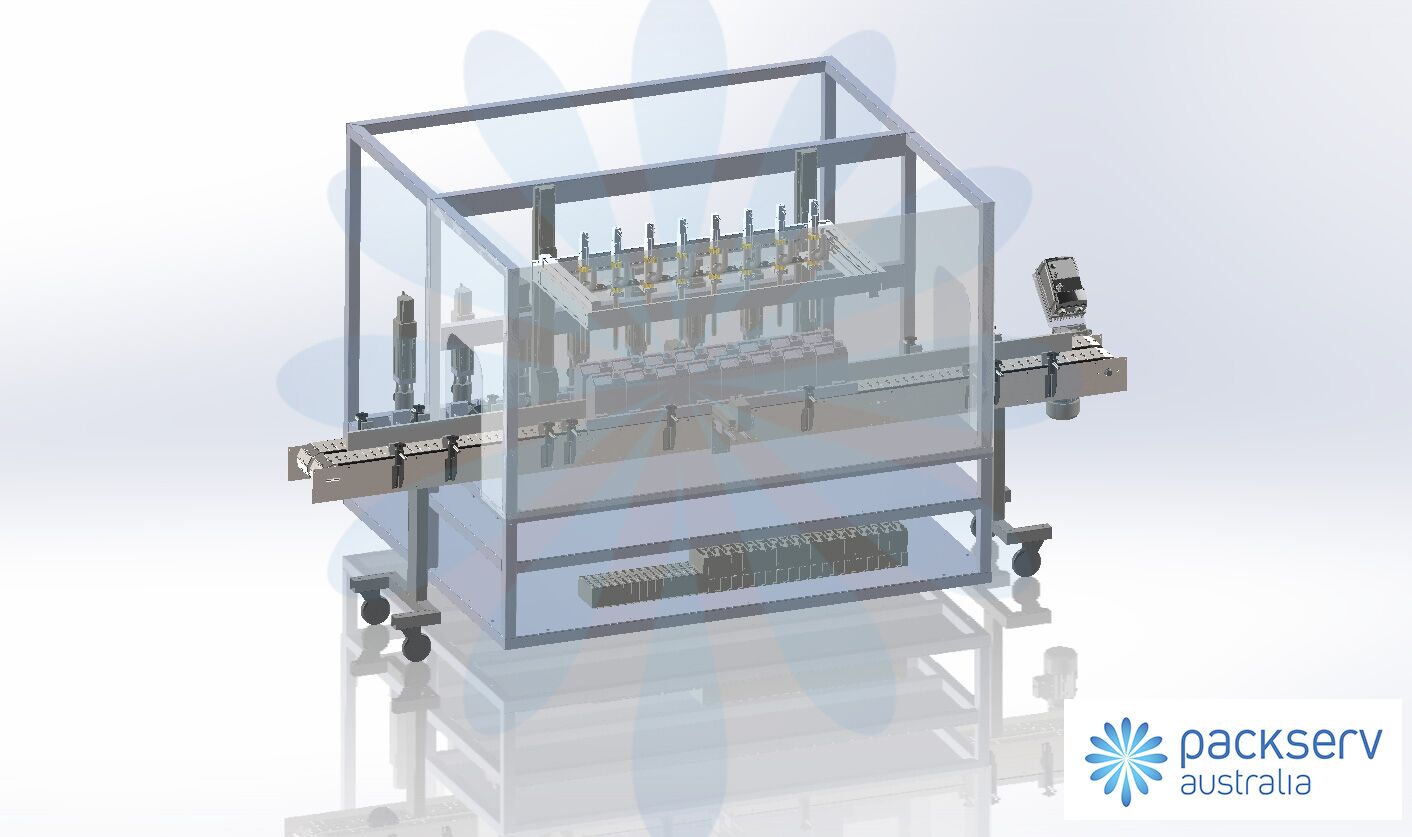

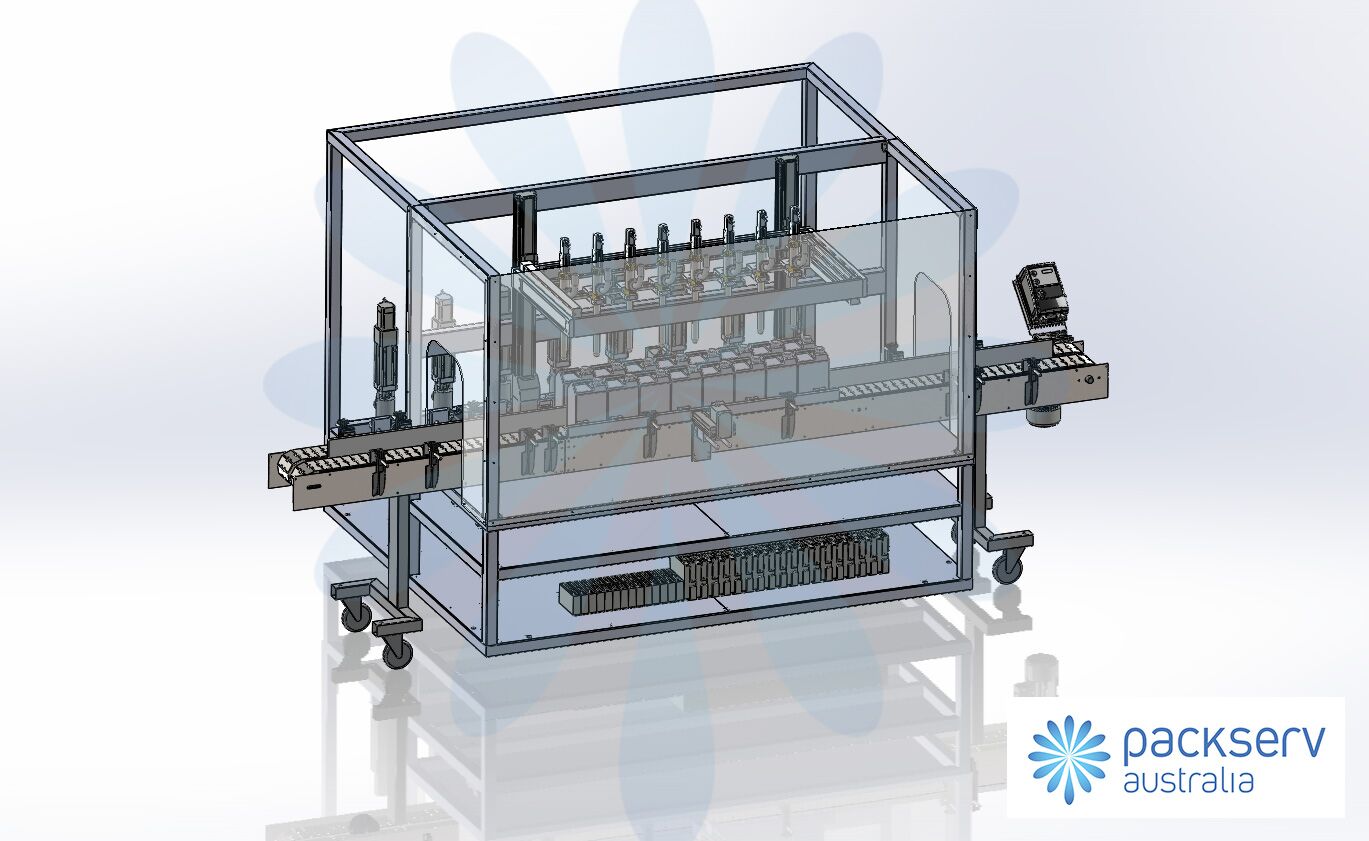

- The PFM-8C-TL includes Positive Shut Off Nozzles (PSON) to increase product flow speeds and reduce pressure, and a Bottom-Up-Fill (BUF) mechanism to reduce the foaming, frothing and over filling of containers on the line.

- Our valve system handles a wide range of liquid products from free-flowing liquids, like toner to honey and even some thick moisturisers. The system can efficiently package products with suspended solids like pasta sauce.

- Safety is paramount, with features such as a “no bottle no fill” safety device, door and cover sensors and a container gating system.

- The PFM-8CTL boasts a welded and polished frame with lockable castors, enabling seamless connection to a continuously running slat conveyor, while remaining mobile.

- The closed-loop auto cleaning system with a tool-free cleaning and parts change-over is designed to minimise downtime and enhance operator efficiency.

Applications

Liquid dispenser, Fluid filler, Beverage filling device, Fluid packaging equipment, Liquid bottler, Fluid dosing machine, Liquid packaging system, Fluid dispensing apparatus, Beverage bottling machine, Liquid packaging machinery, Liquid filling apparatus, Fluid bottling device, Beverage packaging machine, Liquid bottling system, Fluid doser, Liquid bottling equipment, Beverage dosing machine, Liquid filling station, Fluid bottling unit, Beverage packaging system.

Reviews

There are no reviews yet.