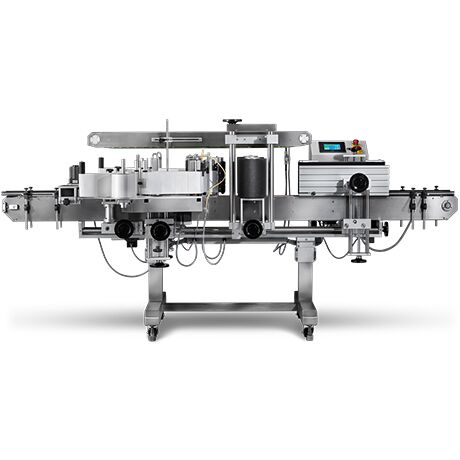

Front & Back Wipe-On Labeller (PL-622).

Pack Leader’s PL-622 Front & Back Wipe-On Labeller is a part of Packserv’s fleet of high-quality, versatile labelling machines. This machine offers fully automated dual labelling heads for wipe-on application of containers requiring front & back labelling. Ideal for flat and near-flat containers this machine can be configured with options to apply a label to almost any container type.

The PL-622 features an overhead conveyor and dual foam-pads in addition to the labelling heads that ensure extra stability. Designed as a continuous, reliable, high-speed labelling machine, it’s mobile between production lines or removal. In compliance with GMP standards, the 304 grade stainless steel and high quality aluminium ensure longevity and corrosion resistance even in the harshest of environments.

The PL-622 incorporates a high-quality LCD control panel featuring inbuilt trouble-shooting and training for operators. Hence ensuring minimal downtime on your production schedule. Additionally, conveyor and labelling head synchronise via control panel to ensure perfect labelling time with minimal setup across products.

See Also: Labelling Machines | Packserv Australia

Reviews

There are no reviews yet.